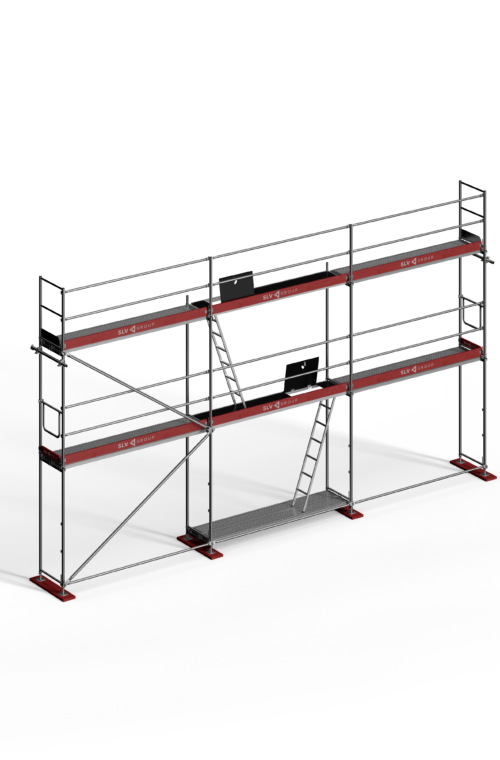

SLV – 70 facade scaffolding

Your safety is our priority

The SLV-70 frame scaffolding is an ideal system for facade works. Thanks to it’s simple and intuitive design, construction work is much faster.

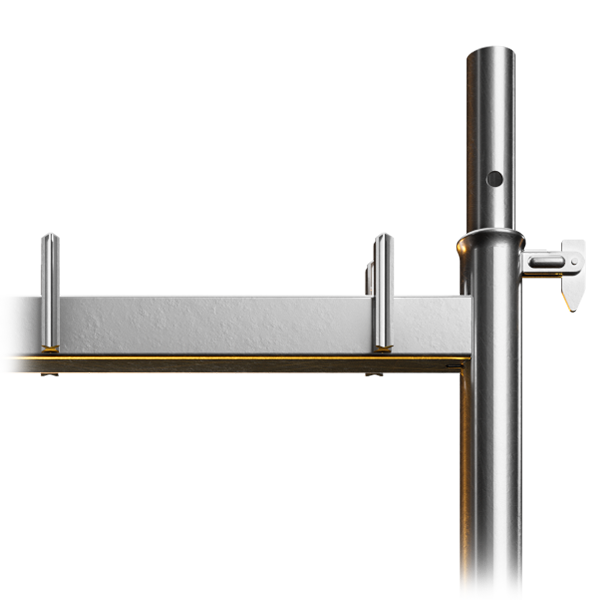

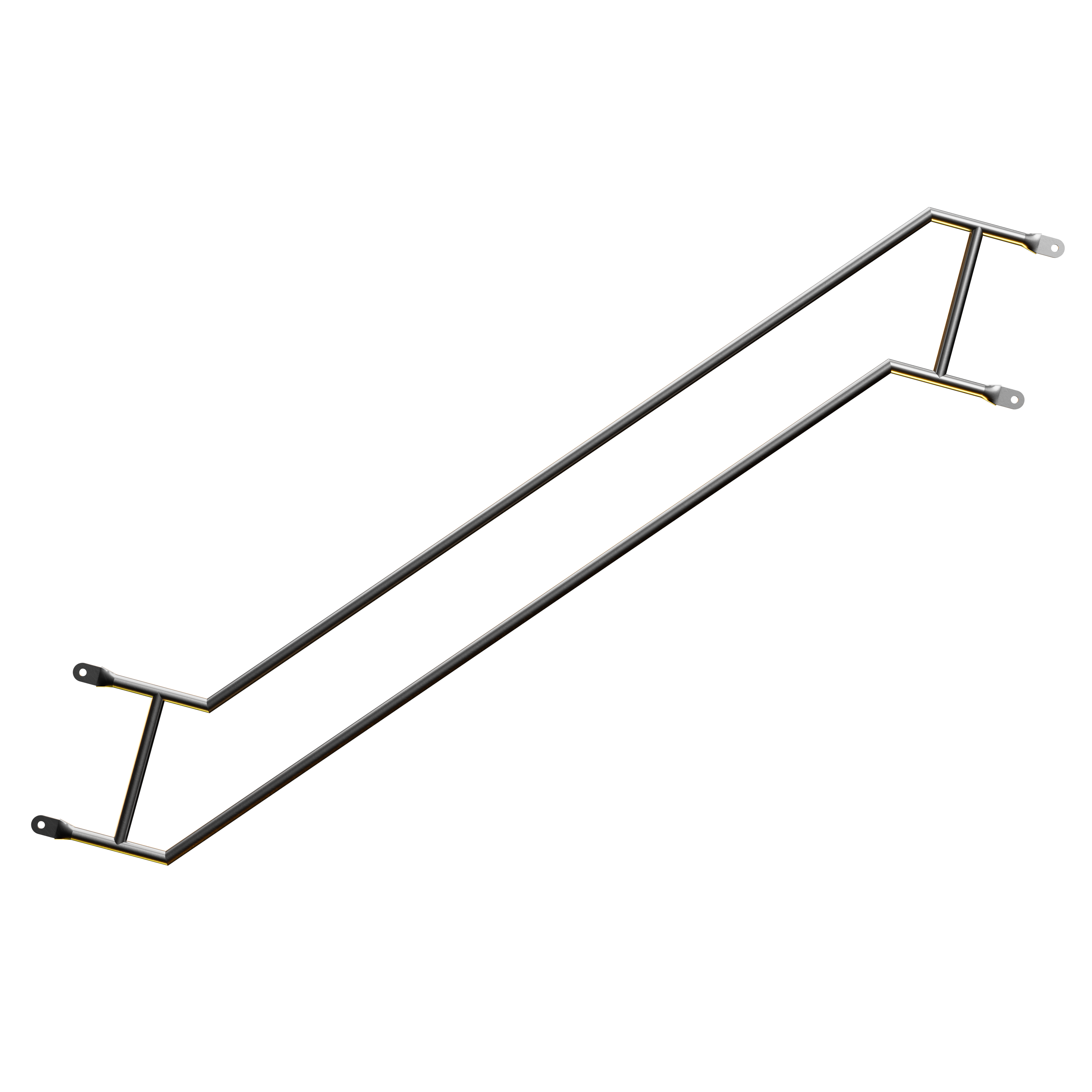

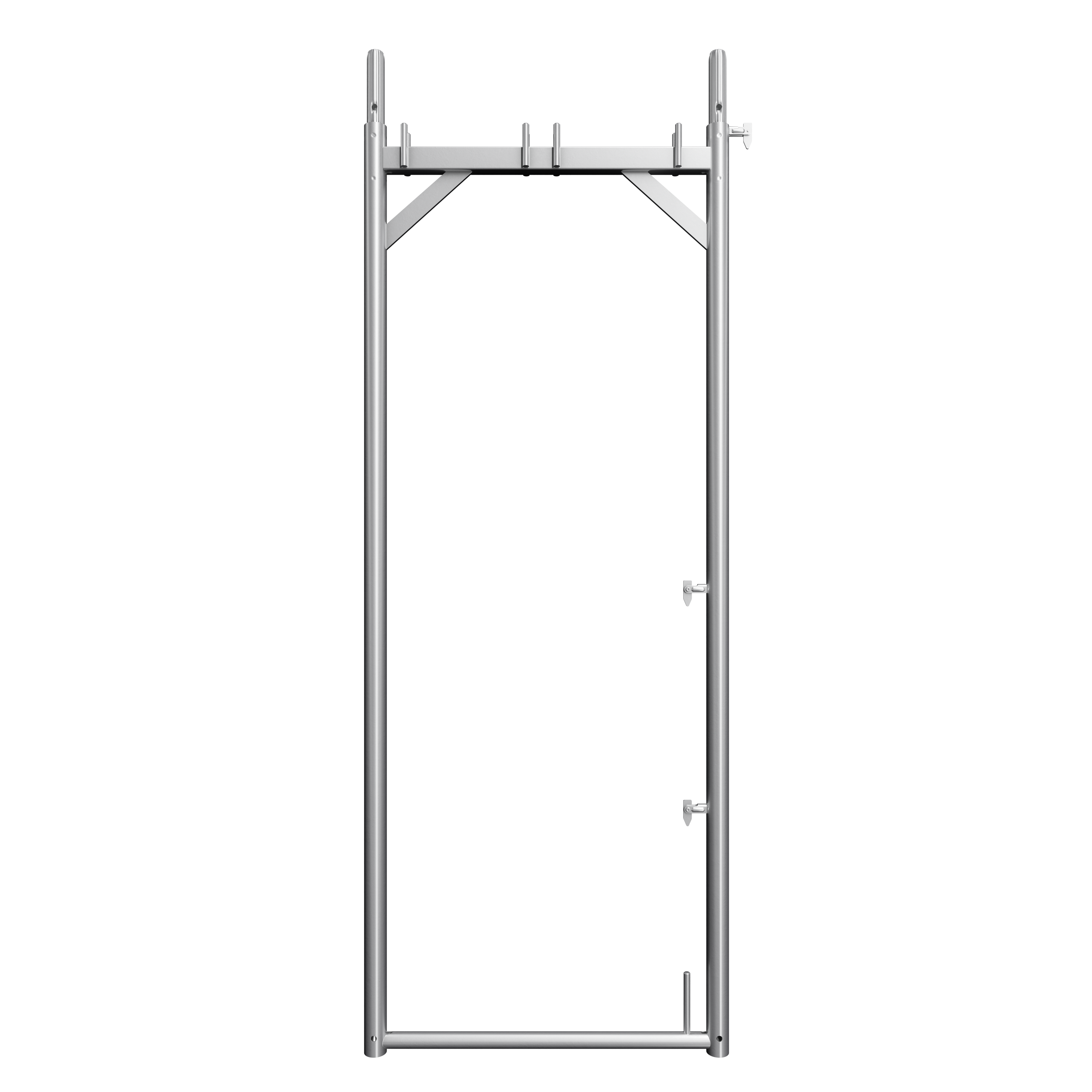

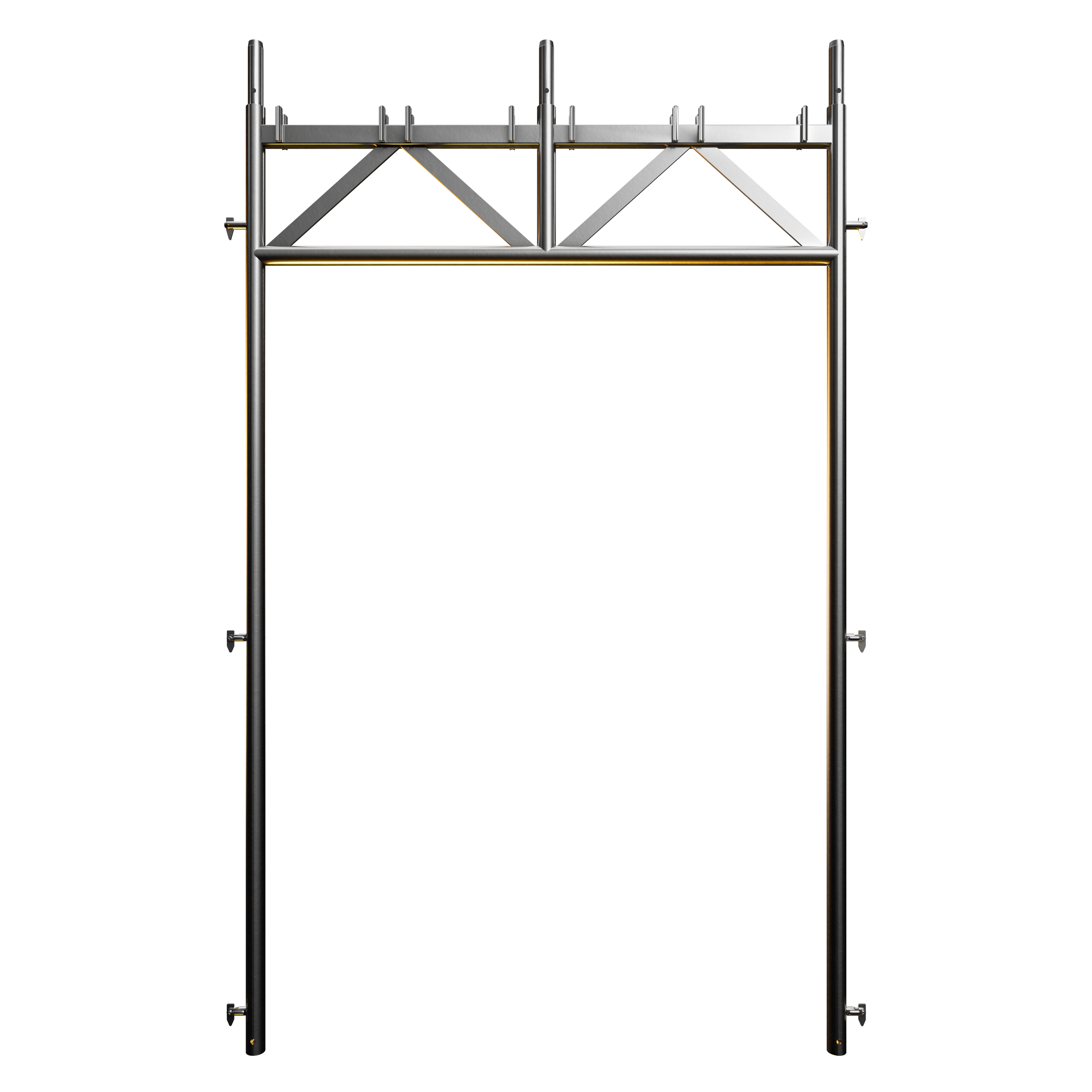

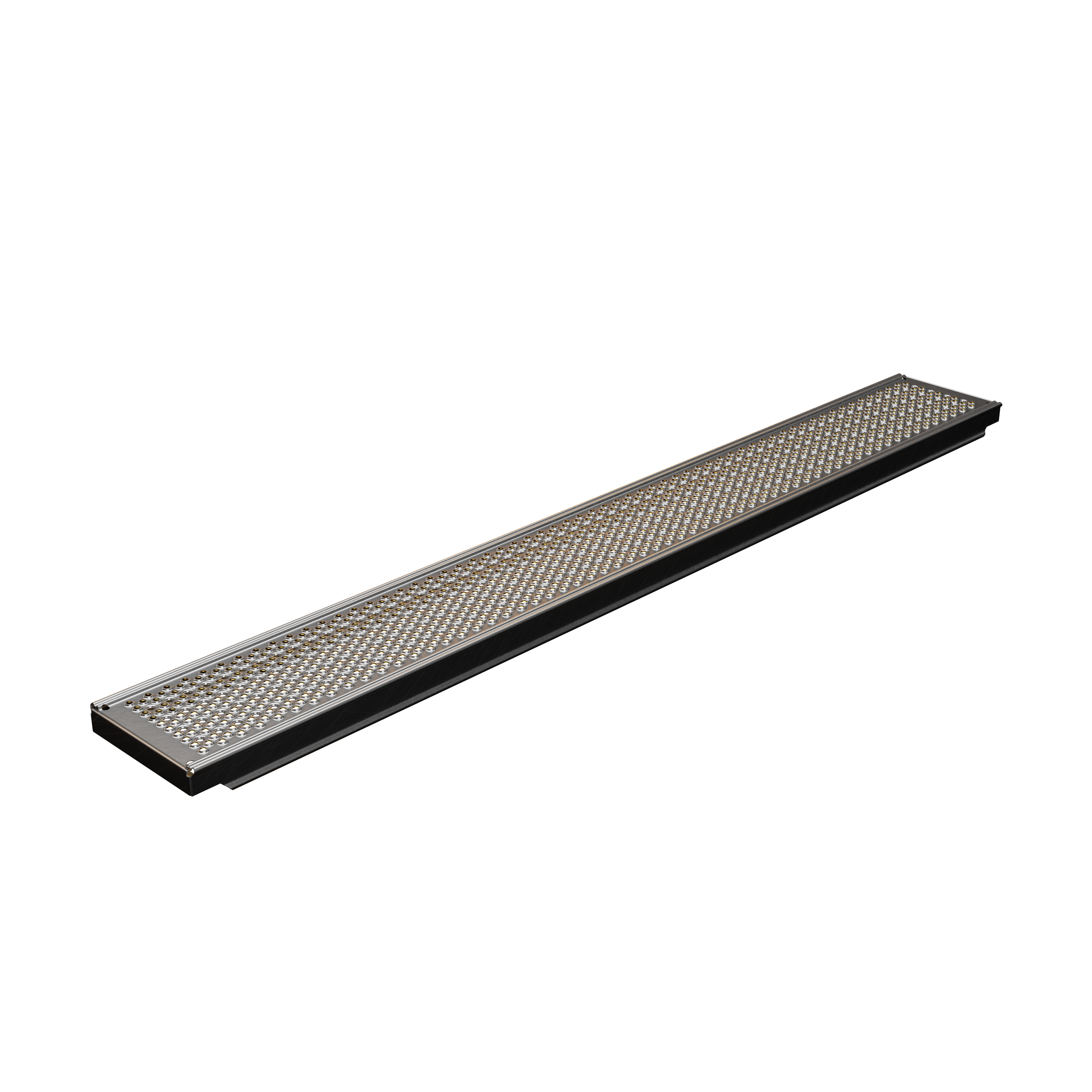

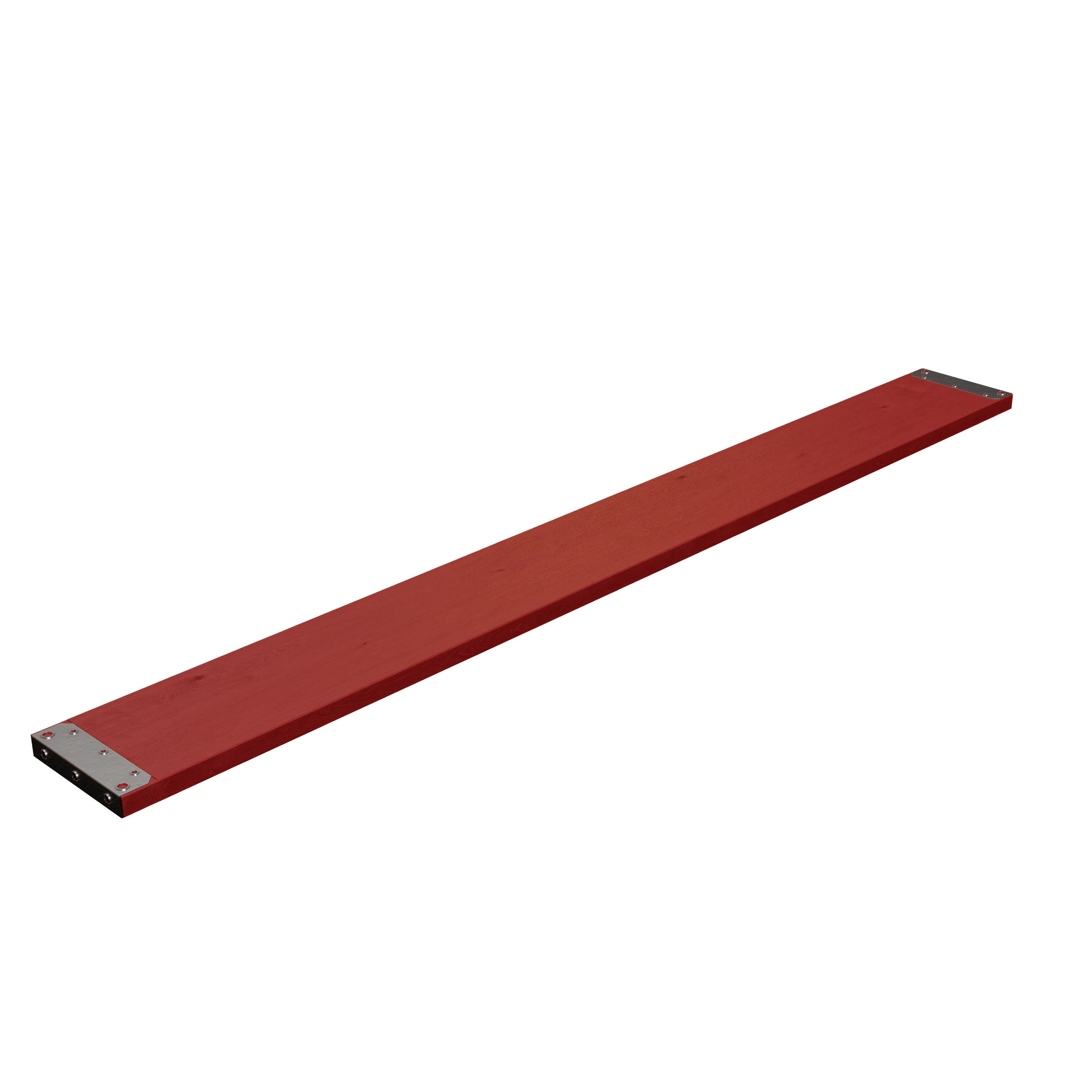

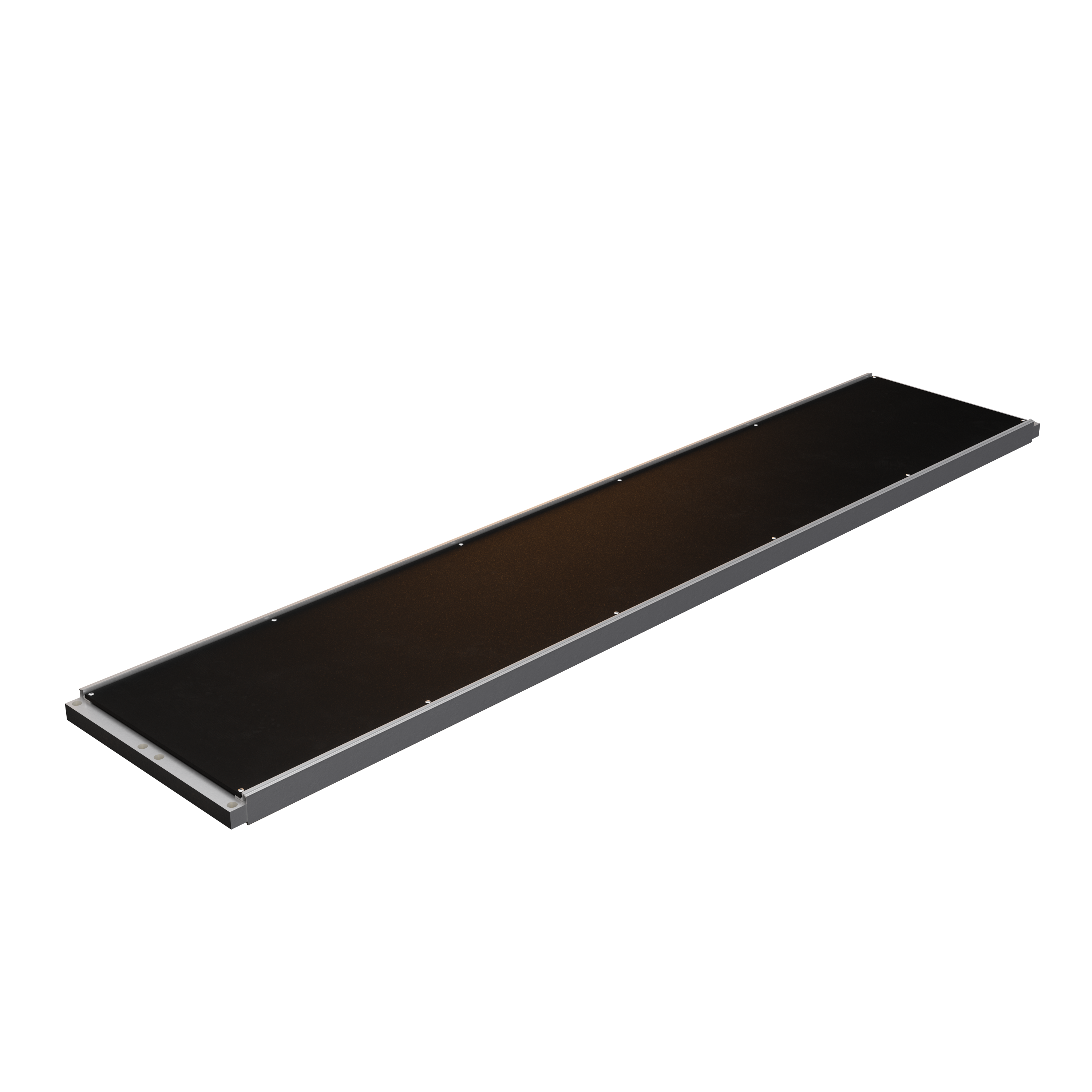

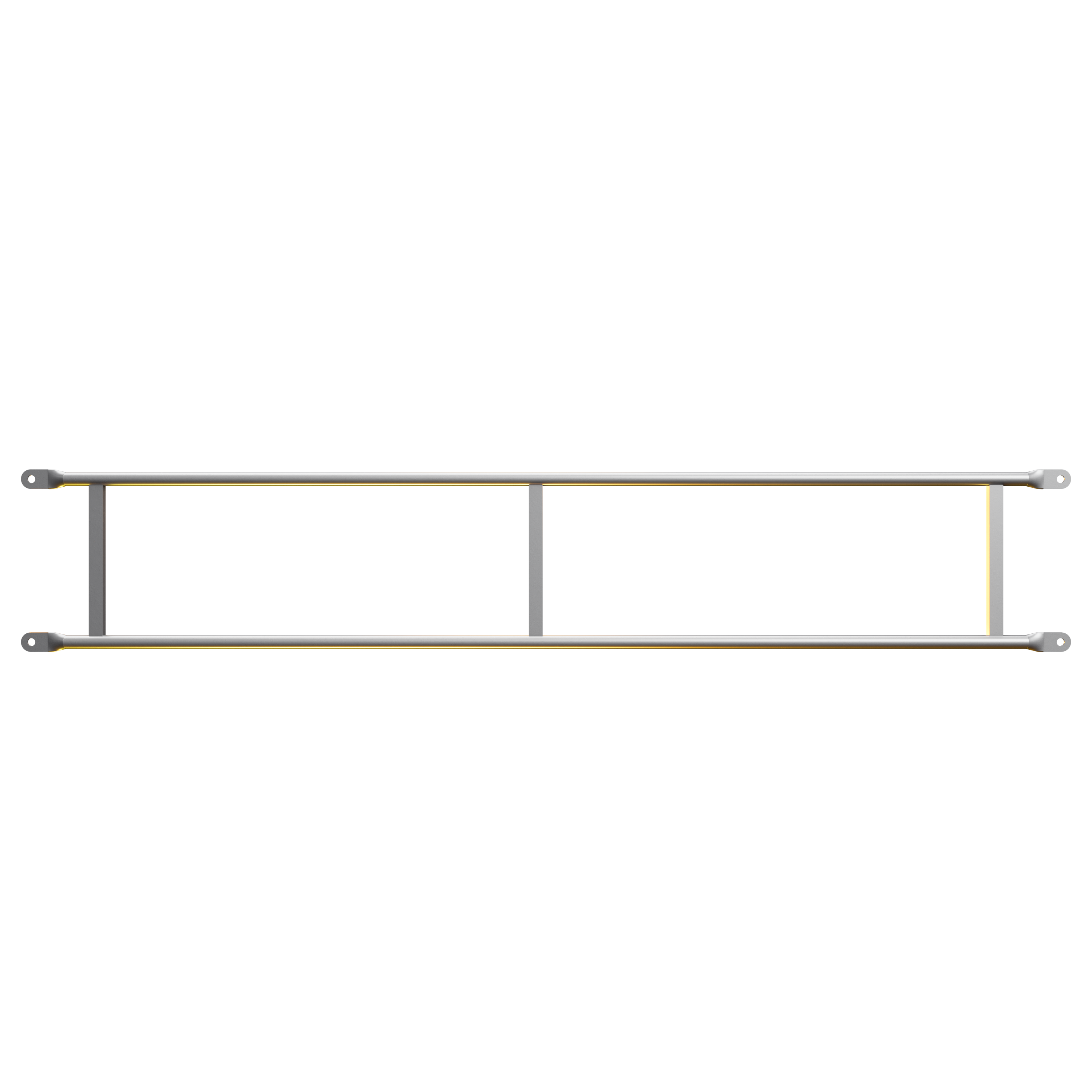

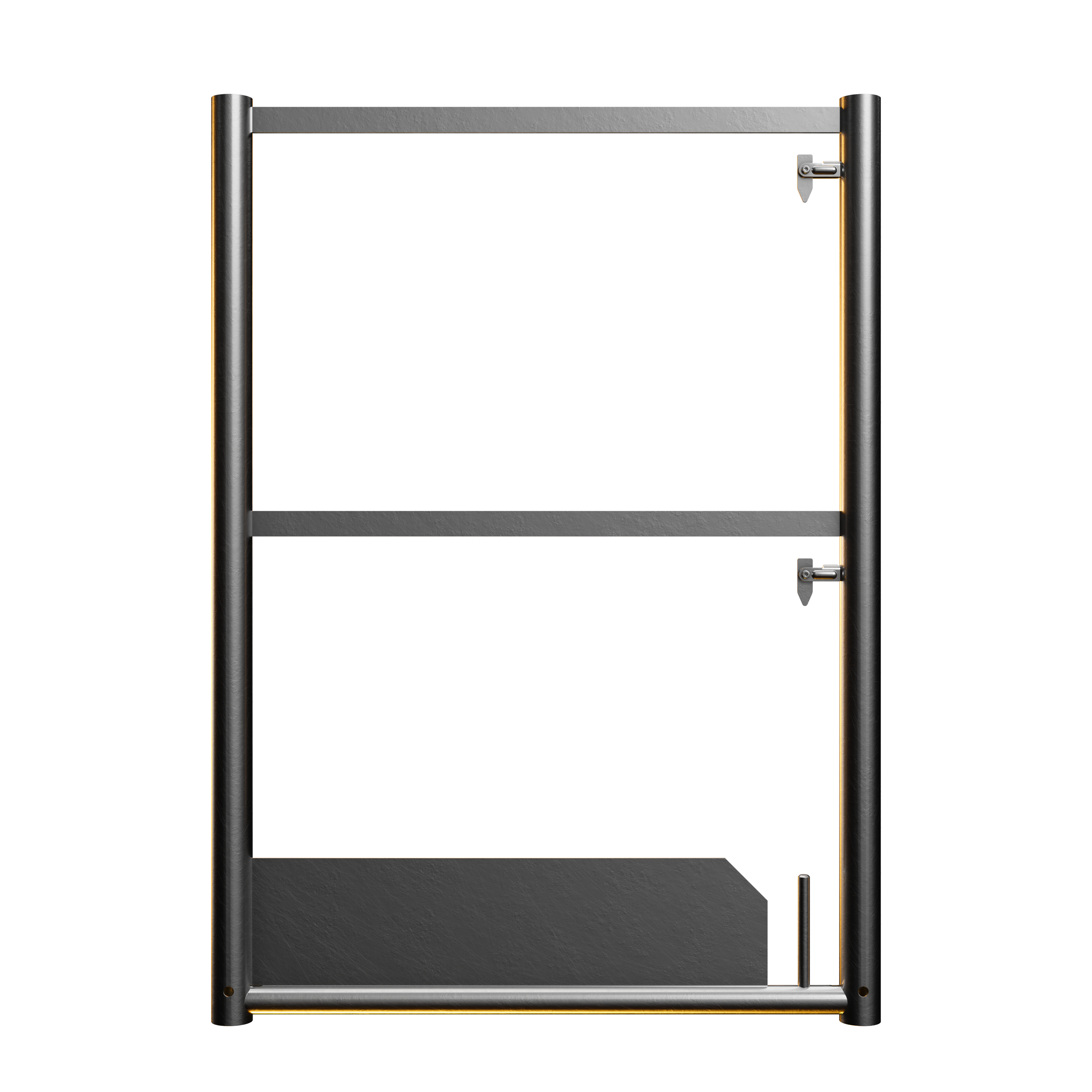

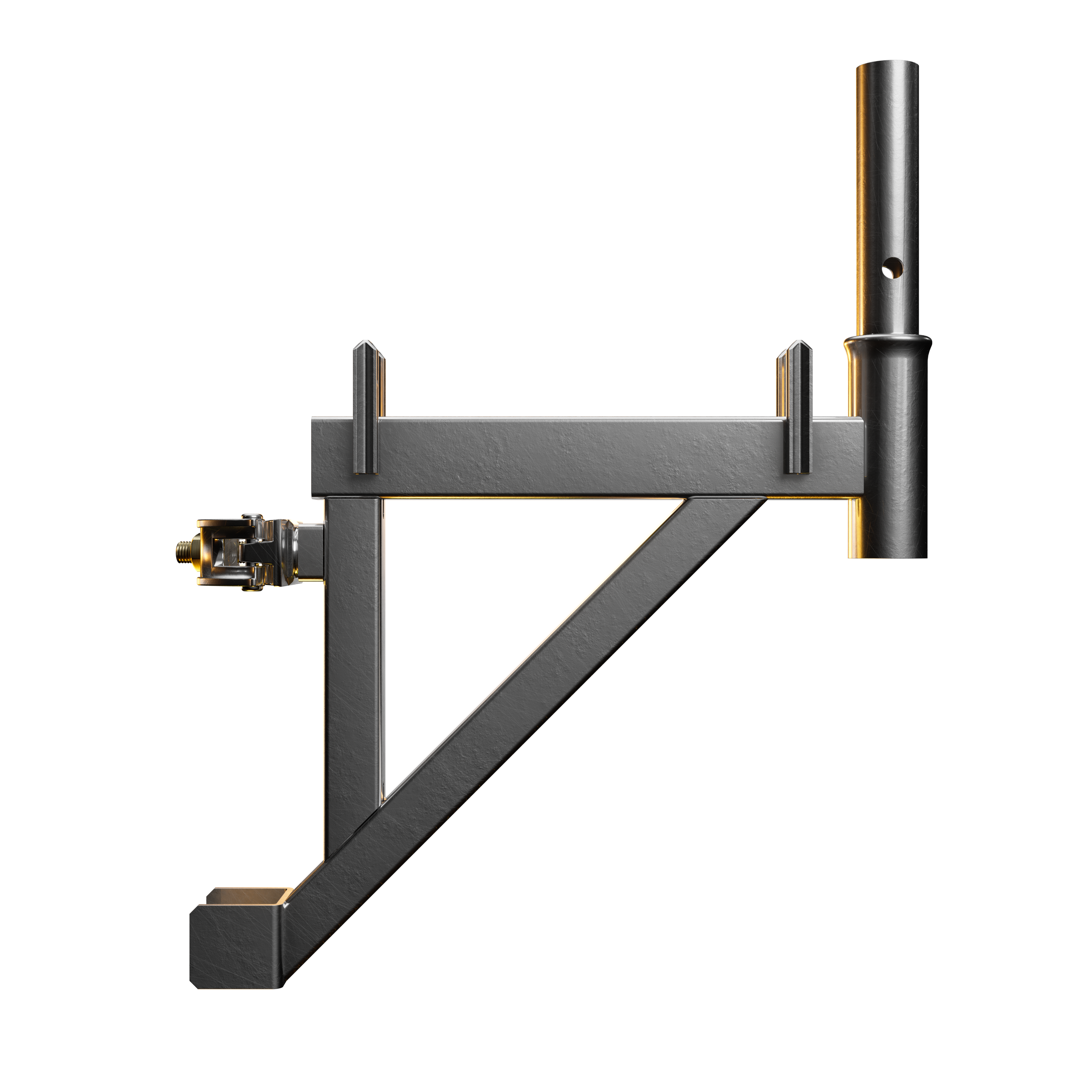

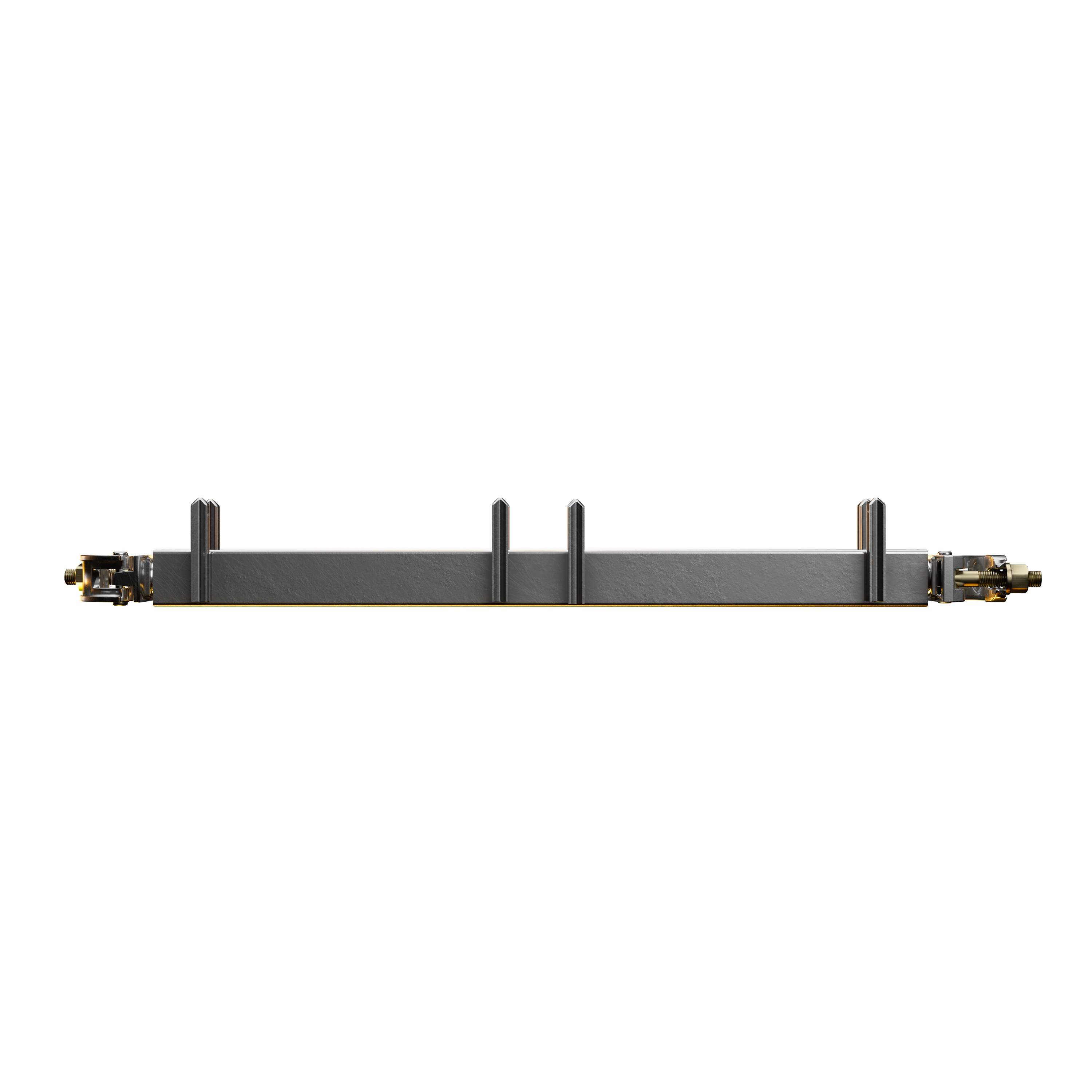

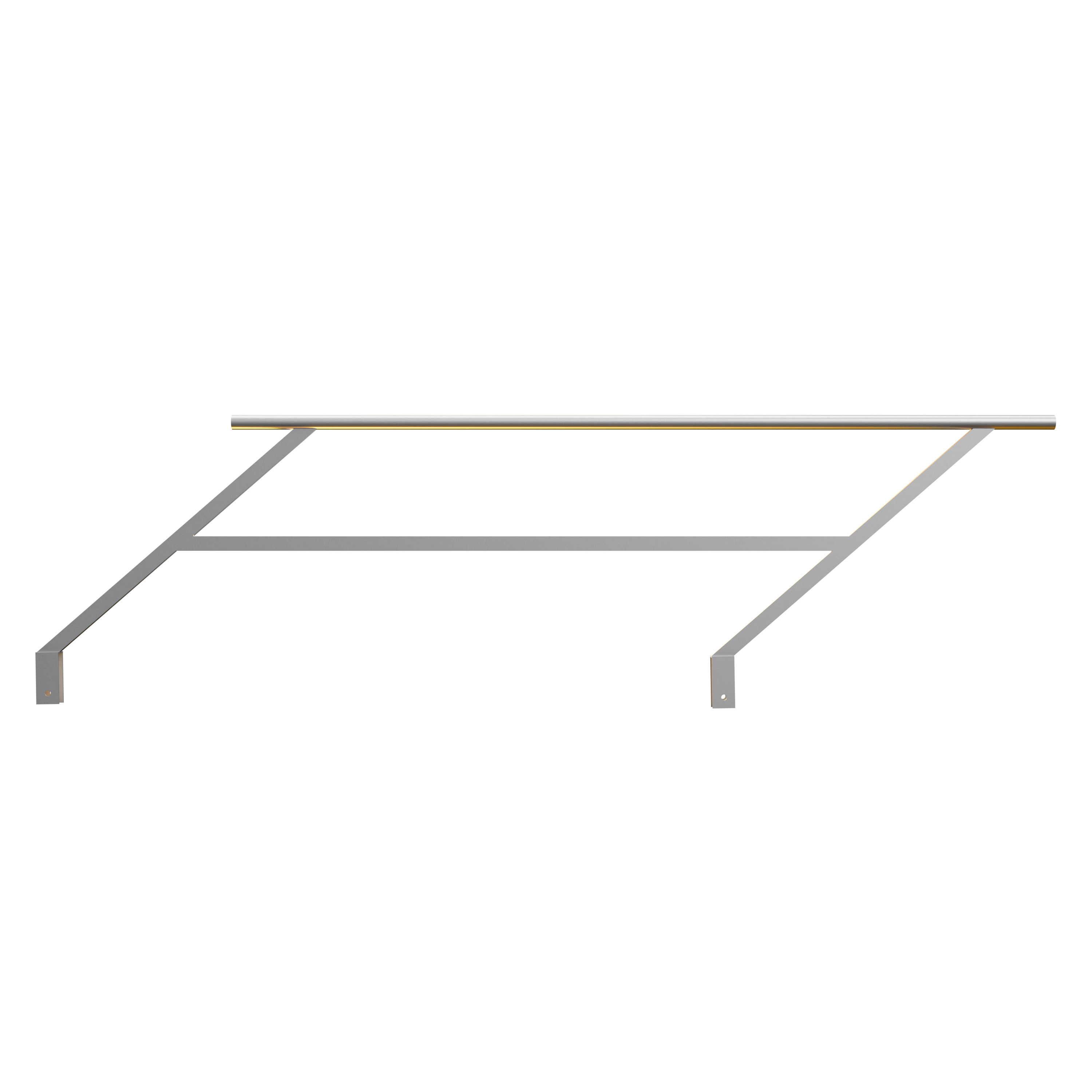

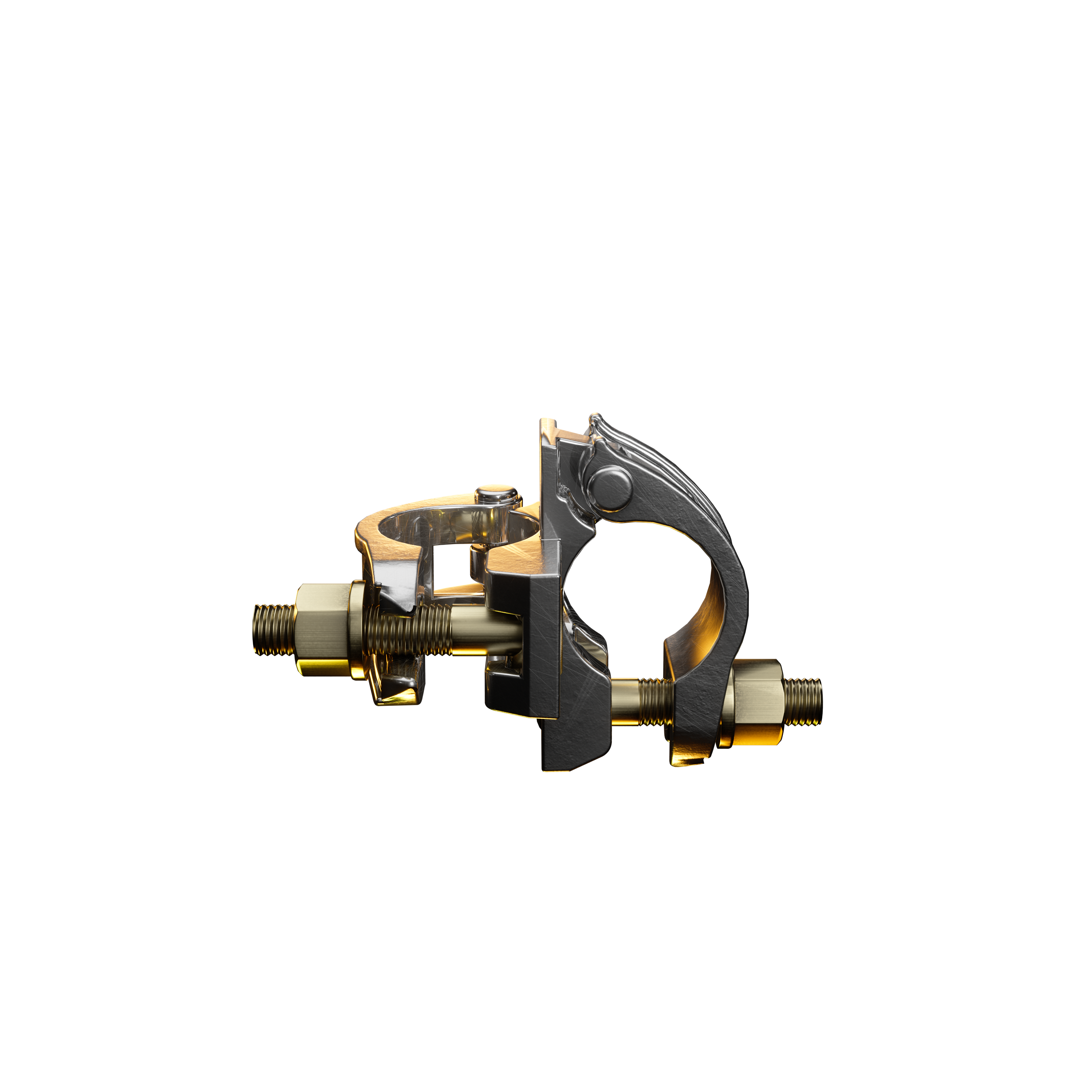

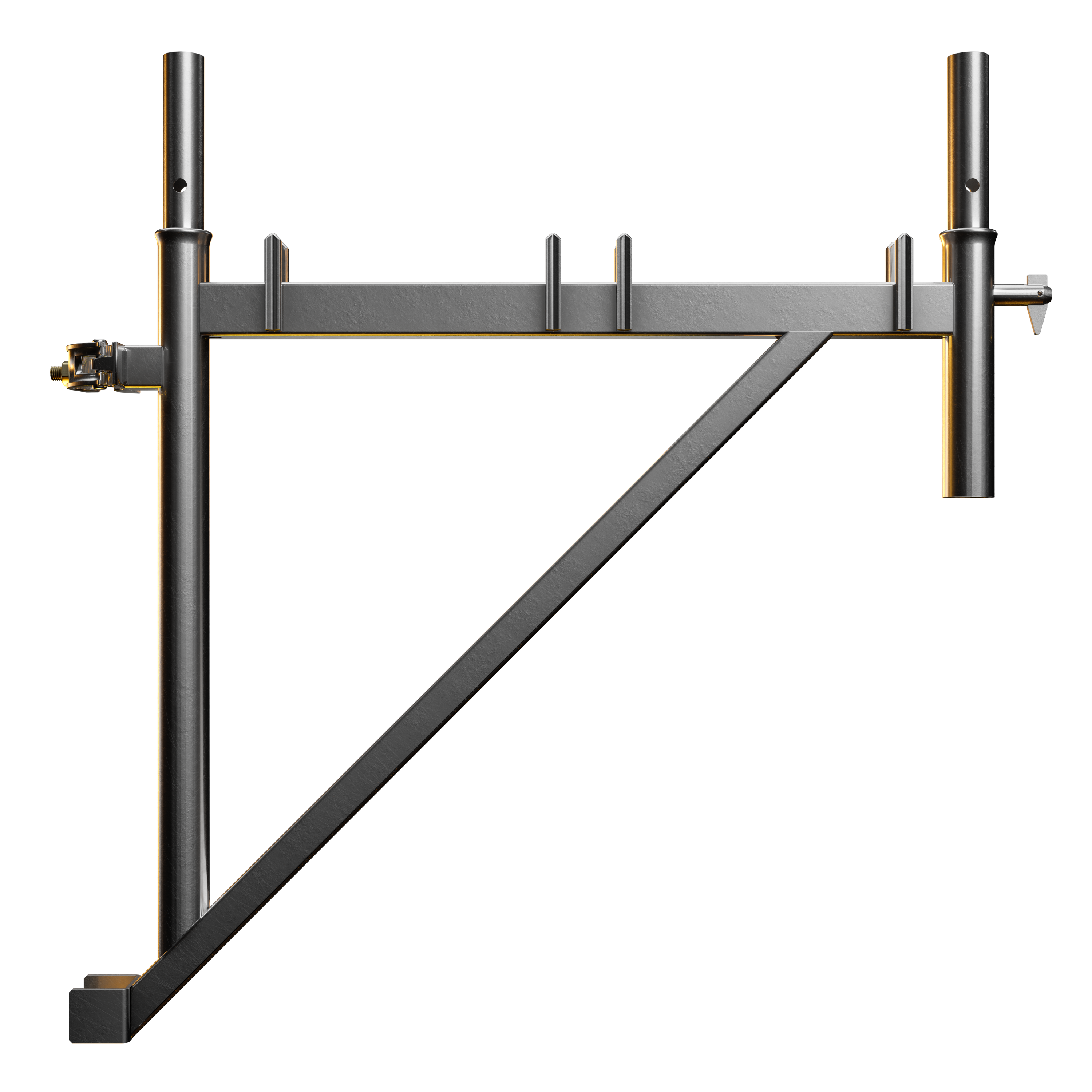

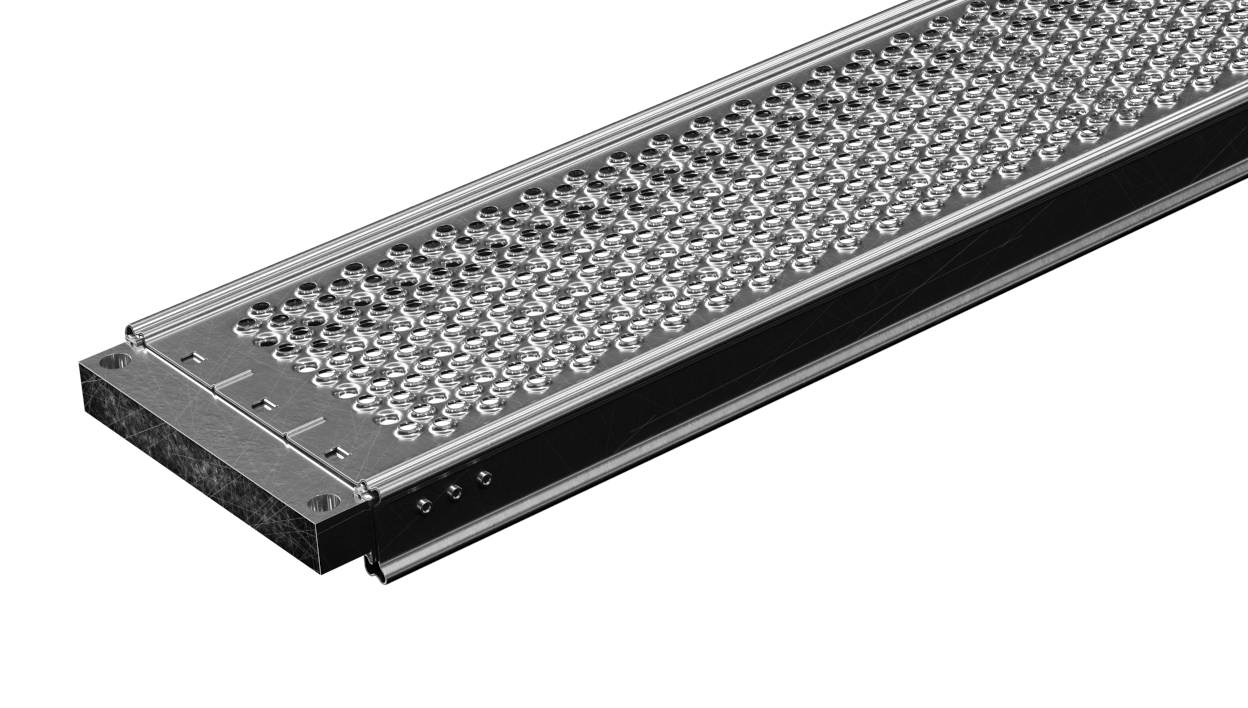

Basic elements of the SLV – 70 system

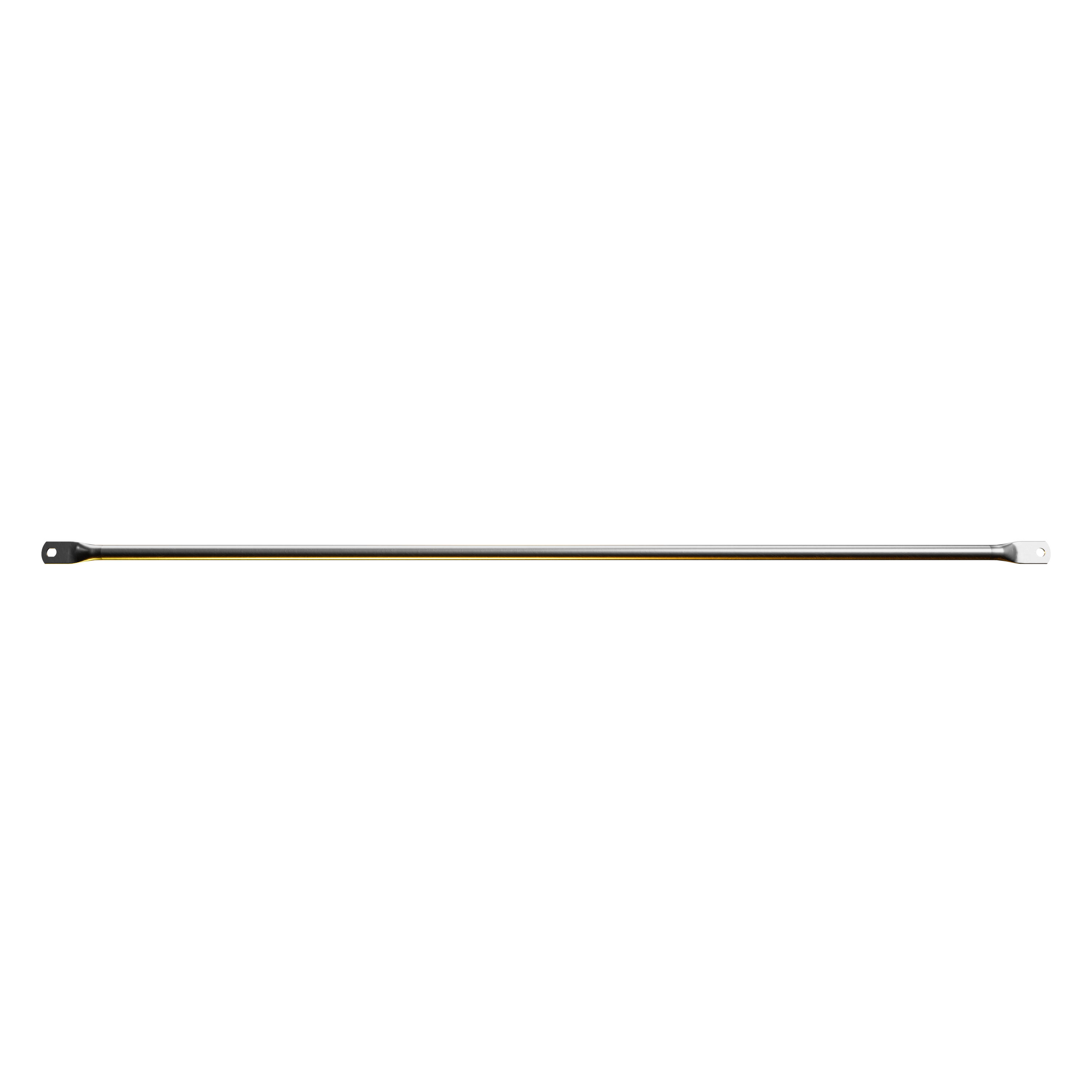

The basic elements of the system are the frame and the platform which serve as the basis of the structure. The platforms are available in sizes from 0.74 m to 3.00 m . The steel frames are made of 48.3 pipe with a 2.7 mm wall . The steel grade is 235 JRH .

with yield strength Re min greater than 280 MPa, most often Re is approx. 280-285 MPa . Before the production process, each pipe section is sent to the Bydgoszcz Institute, which checks whether the certificate is compatible with the delivered batch pipes, in order to avoid “placing” false documents. The pipe is bottled on a machine designed specifically for JRH material, which shapes the pipe.

The machine has three production stages

in order to avoid stresses that could cause microcracks and pipe disqualification.

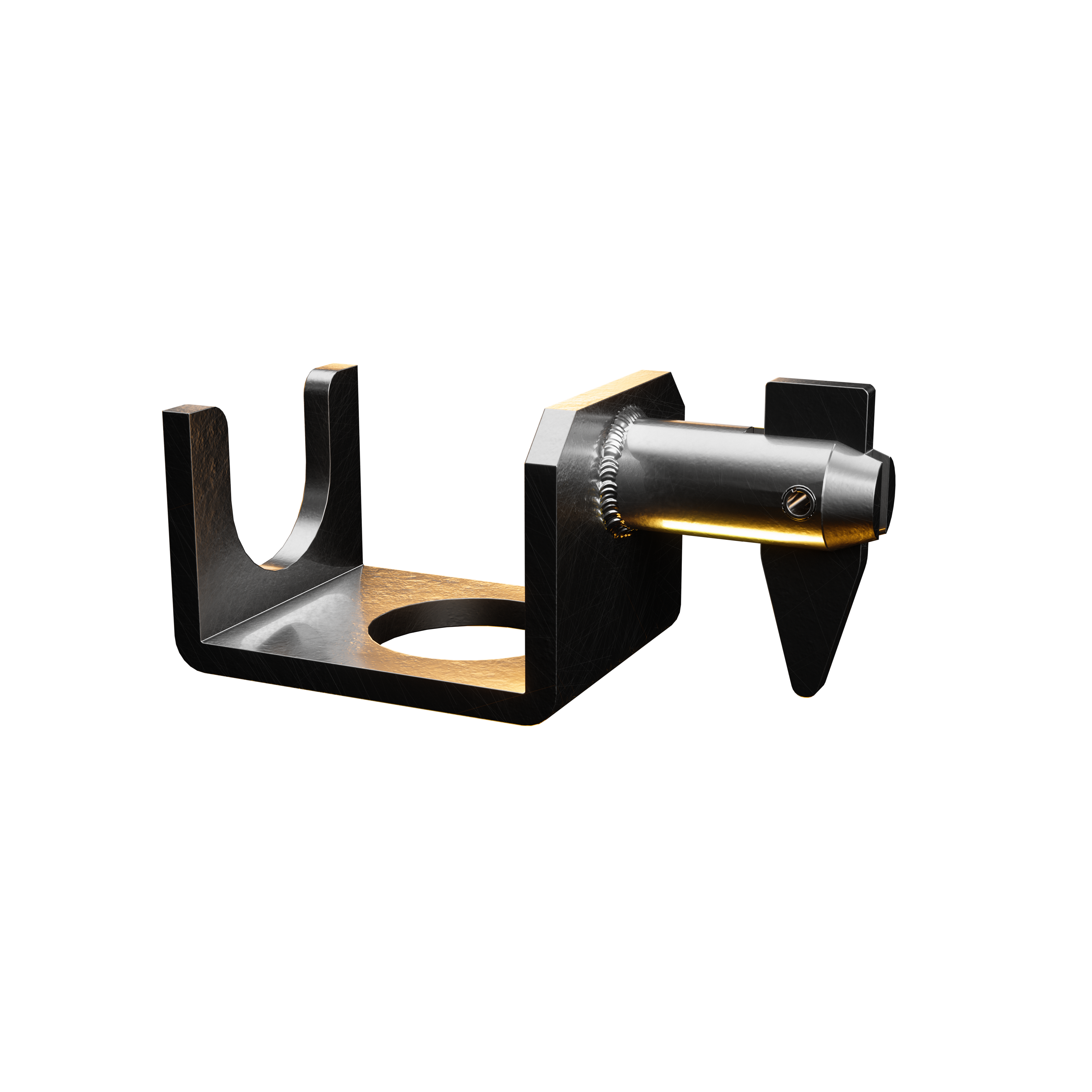

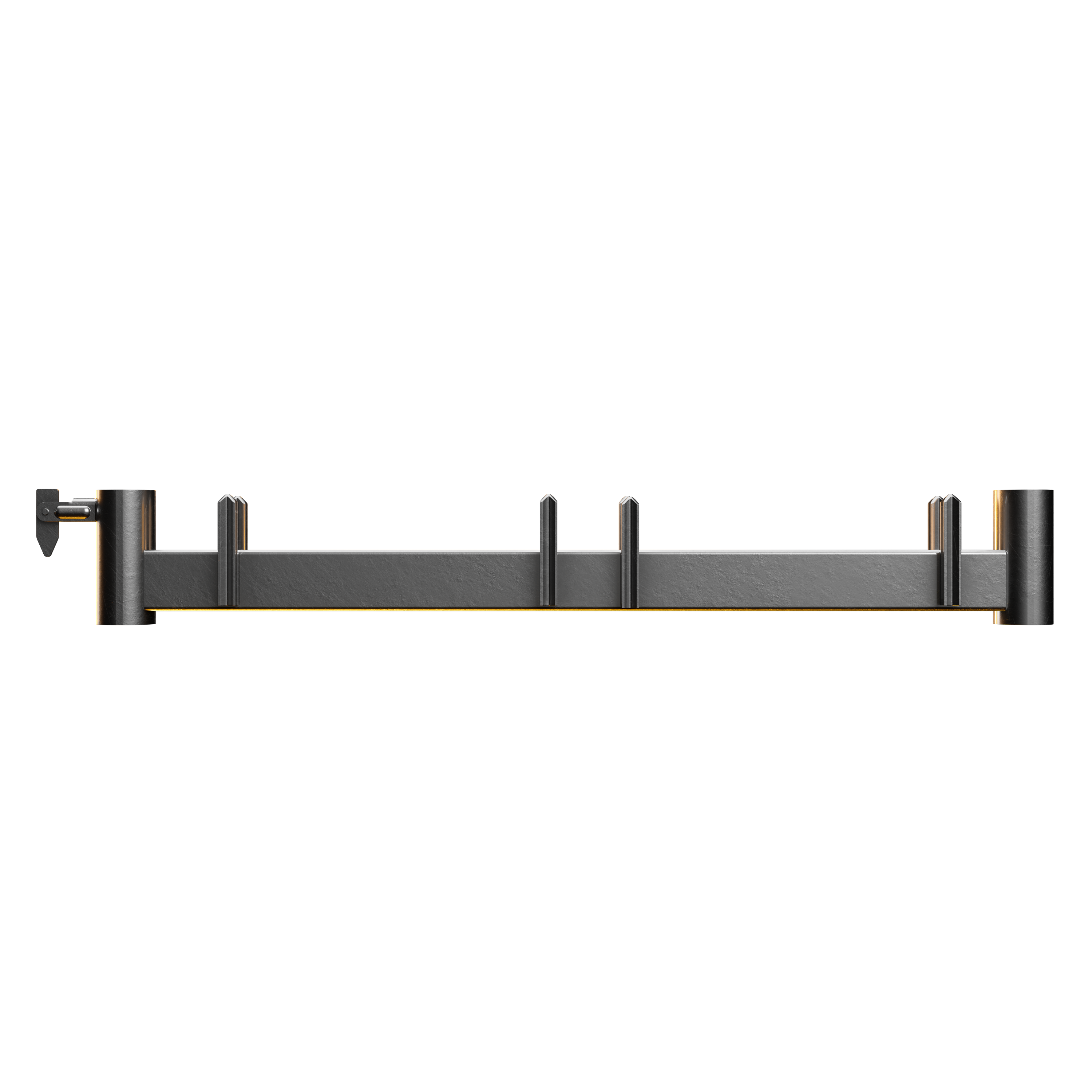

Additionally, reinforced star pins were used as part of the project. All semi-finished products that are used in the production of frames are welded on automatic welding machines – a guarantee of constant quality of welds.

The frames are manufactured on a two-station welding robot.

The machine has three stages of production in order to avoid stress that could cause microcracks and pipe disqualification. Additionally, reinforced star pins were used as part of the frame. All semi-finished products that are used in the production of frames are welded on automatic welding machines – a guarantee of constant quality of welds.

The frames are manufactured on a two-station welding robot

Characteristics and application of the system

The SLV-70 facade scaffolding can be mainly used as:

- Facade scaffolding

- Mobile scaffolding

- Hanging scaffolding

- Industrial scaffolding

- Scaffolding of irregular and complex shape

- Spatial scaffolding

- Work platforms

- Structures of stages and stands

- Stair cases

Advantages of the SLV-70 system

-

Ease and speed of assembly

achieved thanks to the use of prefabricated components -

Stable and rigid structure

and vertical braces allowing to transfer heavy loads -

Secure communication

and free access to workplaces -

Ability to work in an ergonomic and safe position

-

Possibility of vertical communication

through manholes in communication platforms or external staircase -

Guard rails and curbs for safe work

-

Metal elements with a protective zinc coating

increasing their resistance to weather conditions -

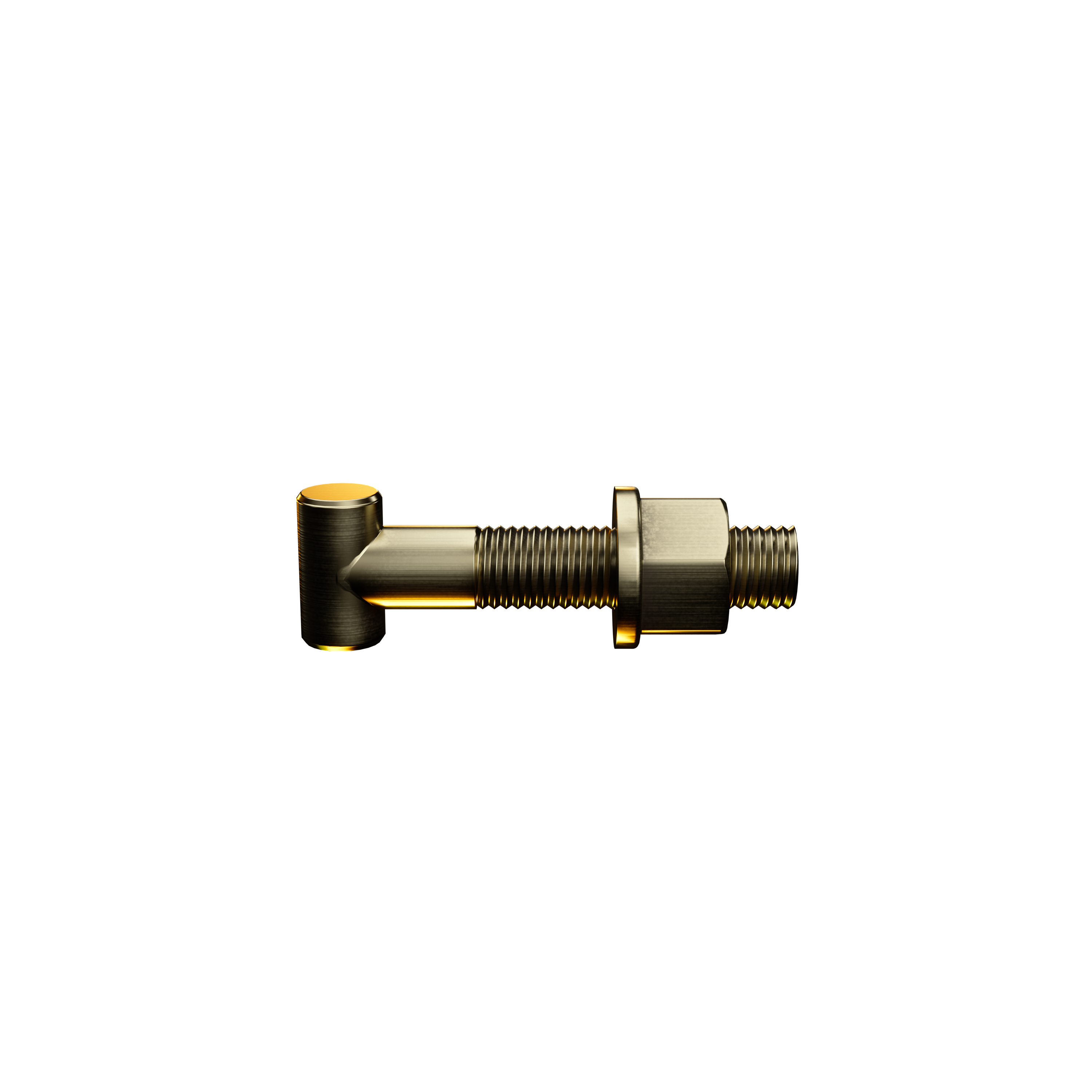

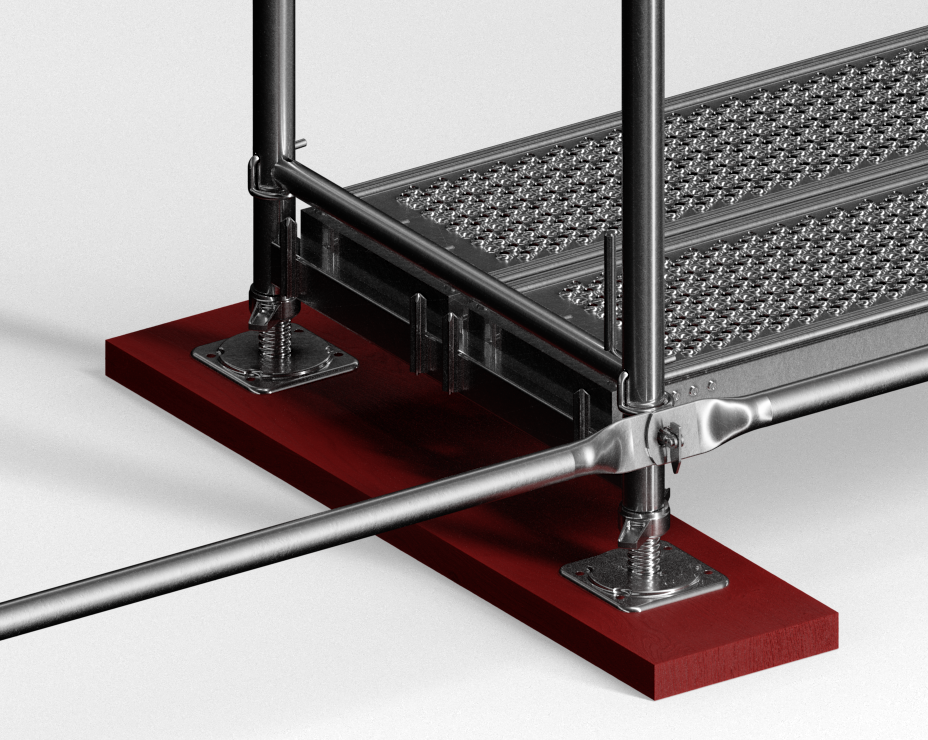

Adaptable to the shape of the substrate

by using screw bases

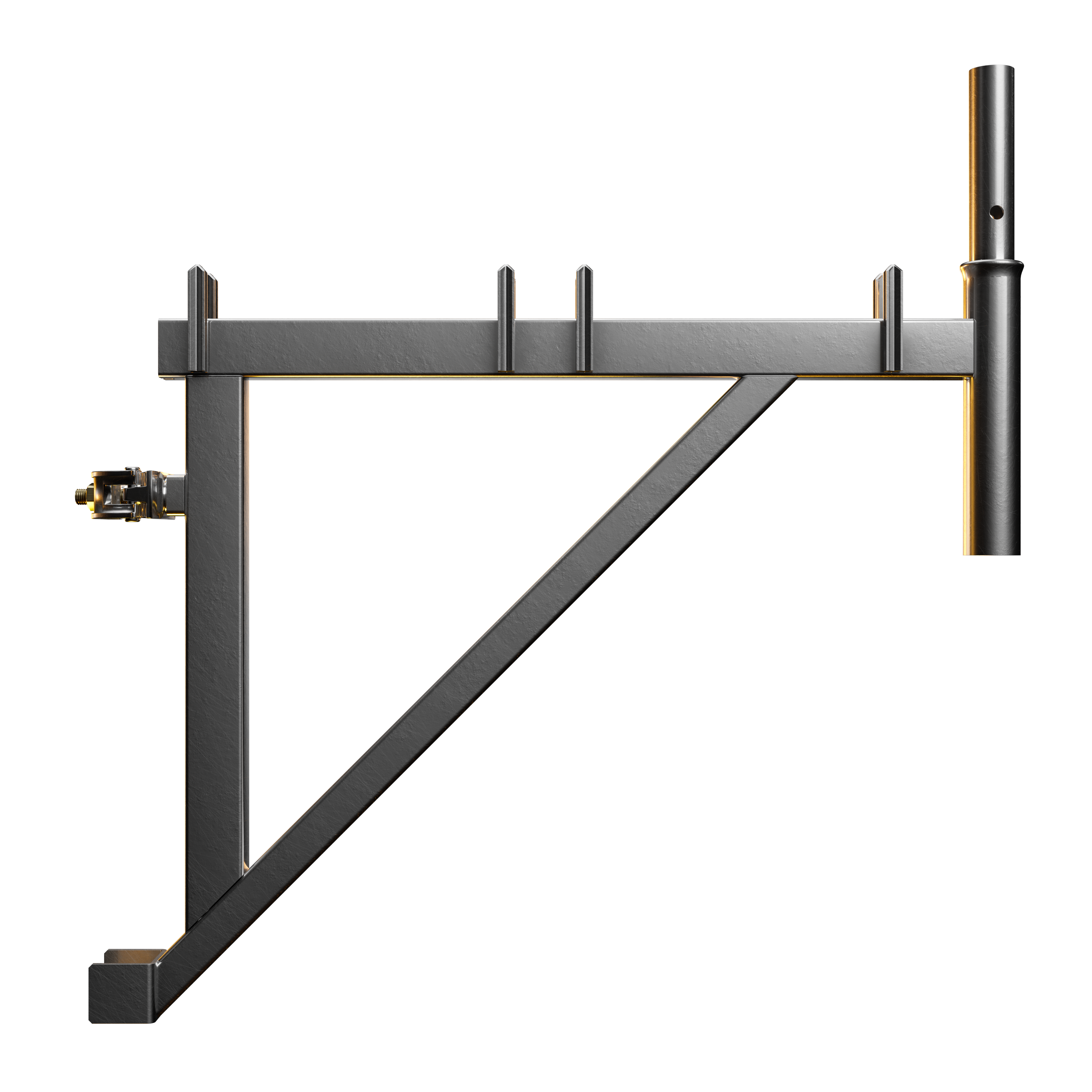

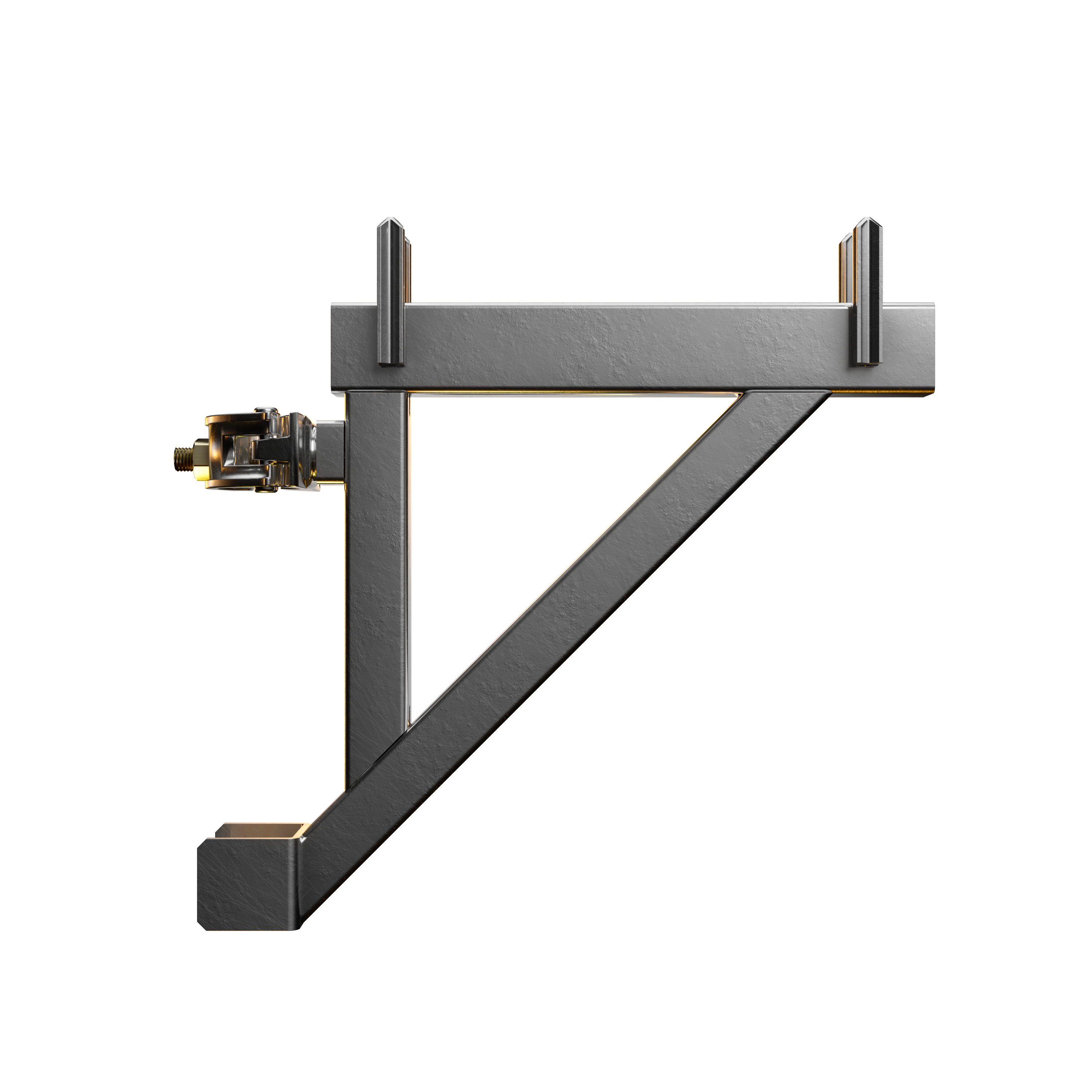

SYSTEM MONTAGE